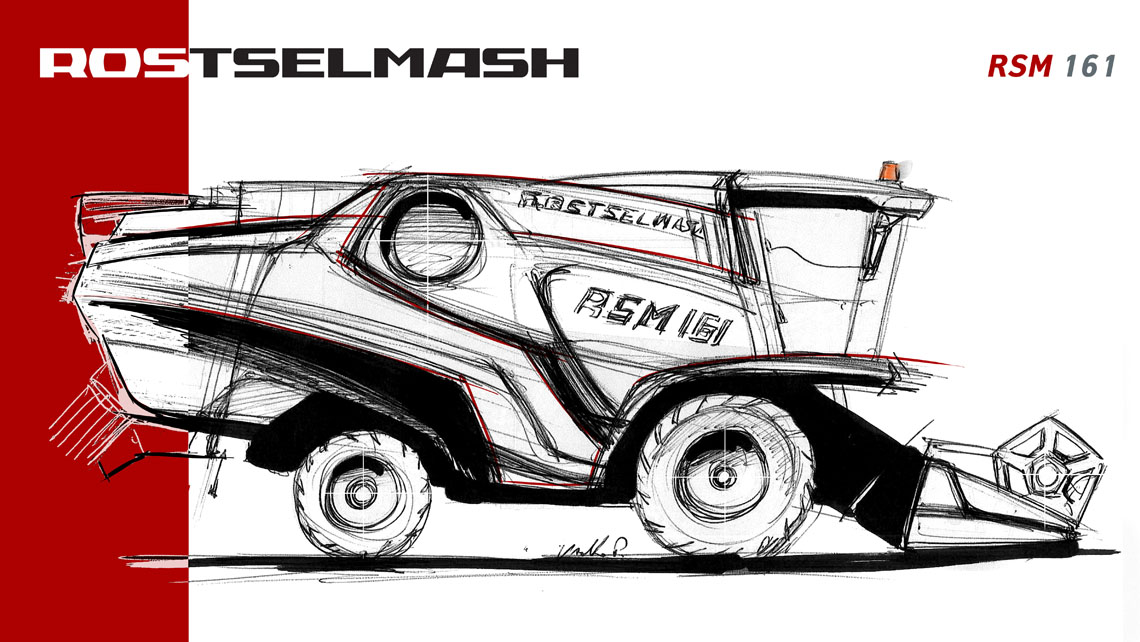

Design

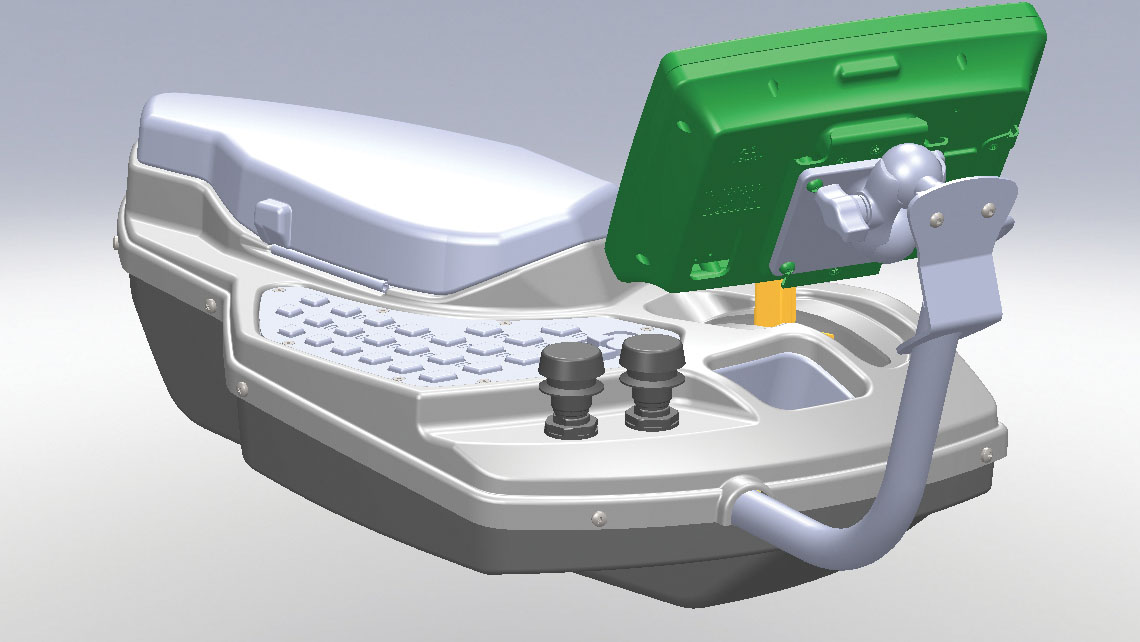

AMV Design drew up plans for the combine-harvester exterior, but its main focus was the cabin, which comes in two sizes and can be mounted on a range of models. The study began with the concept designs, and then moved on to feasibility analysis and sketches. The early designs proved to be extremely innovative and were readily approved by the client.